Advantages

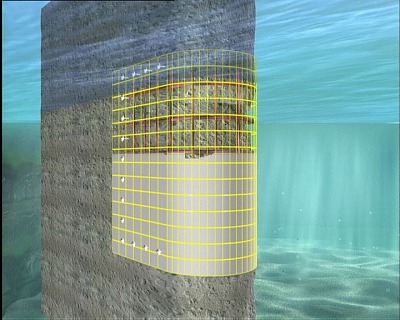

A diver completing underwater repairs

|  |

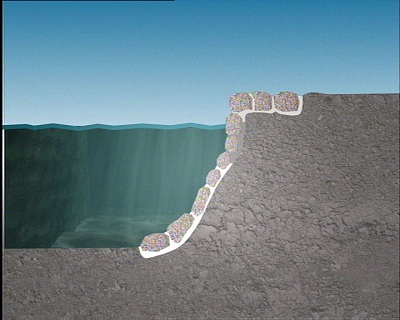

At underwater sites, a diver examines and maps out the damage. Impurities and crumbling mortar are removed with a water chisel at 600-1000 bar or a high-pressure water jet. The actual repairs are then done by divers. Moulds are usually not necessary. Even large repair jobs can be done quickly and easily with the help of a shutter mesh. If moulds are used, they are lightweight and quick to install.

|  |

A quicker method

- Work can be done in flowing water

- Moulds not needed for repairs to joints and crevices

An efficient repair method

- No interruptions in production or use

- No need for coffer dams

- No need to pump out reservoirs

- No need to dry the repair area

- Diversion discharges are not needed in hydro power plants

PowerMortar withstands even the most severe conditions. It sets at low temperatures and resists erosion caused by freezing.

Wide range of uses

- Suitable for repairs to all types of concrete and masonry structures

- Repairs even vertical joints underwater

- Weather damage at water surface level can be repaired at the original surface