|

|

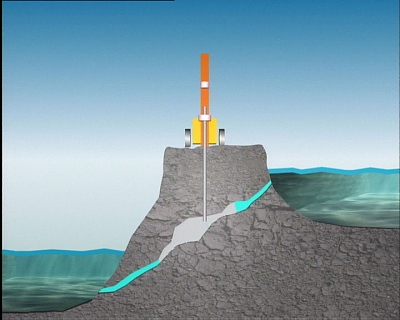

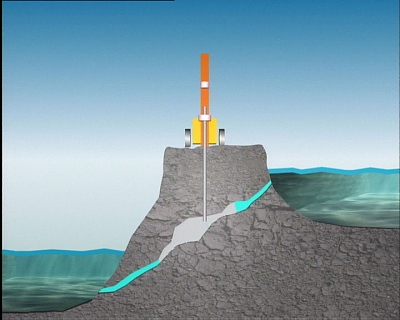

Applications for PowerMortarUnderwater PowerMortar Water and thermal variations are enemies of concrete and stone masonry structures. In particular, flowing water and repeated freezing will corrode surfaces and cause mortar joints to weather. Generally, repair work has been carried out by drying the area to be repaired with the aid of coffer dams. This is always a major undertaking. For example, when a hydroelectric plant structure is dried out for work to be done, the loss of power generation can have significant economic consequences. Now there is a solution: POWERMORTAR. Underwater PowerMortar is a mortar developed for underwater repairs to stone and concrete structures. Its excellent adhesion to stone and concrete surfaces, along with its rapid hardening properties, make PowerMortar an efficient method for underwater repairs, even in rapidly-flowing water. PowerMortar and divers at work

| Traditional repair method

|

Underwater PowerMortar can be used, for instance, in the following applications:| | - Hydropower plants

- Dams

- Canals

- Bridges

- Harbours

- Anchorages

- Tunnels

- Caves

| | | | - Stone masonry joints

- Cracks in concrete

- Cracks in stone

- Weather damage

- Breakage

- Grizzly sides

- Erosion damage

- Joint failures

- Defects during construction

| |

Above-water PowerMortar Damage often extends above the water surface as well. Typical examples are weather damage, cracks and joints. Thanks to its viscosity and adhesiveness, PowerMortar is easy to place on the repair location with no need for moulds. PowerMortar is especially suitable for locations that require extreme strength and a high degree of resistance to wear. Repair sites remain clean, because no chalk is released from the mortar.  On the shore of Kaivopuisto park in Helsinki, Finland PowerGroutThe composition of PowerMortar injection mortars can be varied according to the repair location and conditions. For underwater locations, injection work should generally go from the wet area to the clean surfaces. For large fractures in rock, the mortar's viscosity and superior adhesiveness mean that only moderate quantities are needed. Fortum's technology centre has developed products for injecting into earthen dams, which are particularly appropriate for the nature of the seepage and the construction of the dam.  |  Isohaara power plant in Kemi, Finland Isohaara power plant in Kemi, Finland |

PowerShotcretePowerMortar is used in the so-called "wet method" for sprayed concrete. Applications include rock caves, where the product can be injected or drained. PowerMortar can achieve tremendously high strength in sprayed concrete.  Public shelter in Vantaa, Finland |  PowerMortar in sprayed concrete, PowerMortar in sprayed concrete, Vantaa, Finland |

Anchoring mortar PowerMortar's great compression strength, rapid drying, and ability to be pumped into wet or even water-filled boreholes, make PowerMortar an effective anchoring mortar.

|

Isohaara power plant in Kemi, Finland

Isohaara power plant in Kemi, Finland

PowerMortar in sprayed concrete,

PowerMortar in sprayed concrete,